Hydrogen

Hydrogen case study

Climate change and air quality concerns have pushed clean energy up the global agenda. As we switch over to new, cleaner technologies and fuels, our experience of using power, heat and transport are going to change, transforming the way we live, work and get from A to B. Explore the sections below to find out more.

- What can we use hydrogen for?

It can be used for heat and power, as part of the production of other chemicals, or to store energy for later use - Supporting renewable energy

Hydrogen can act as an energy store as a backup for renewable sources like solar power or wind power - Using hydrogen safely

Preventing leaks, adding a scent, transporting it carefully and controlled burning can help minimise risks

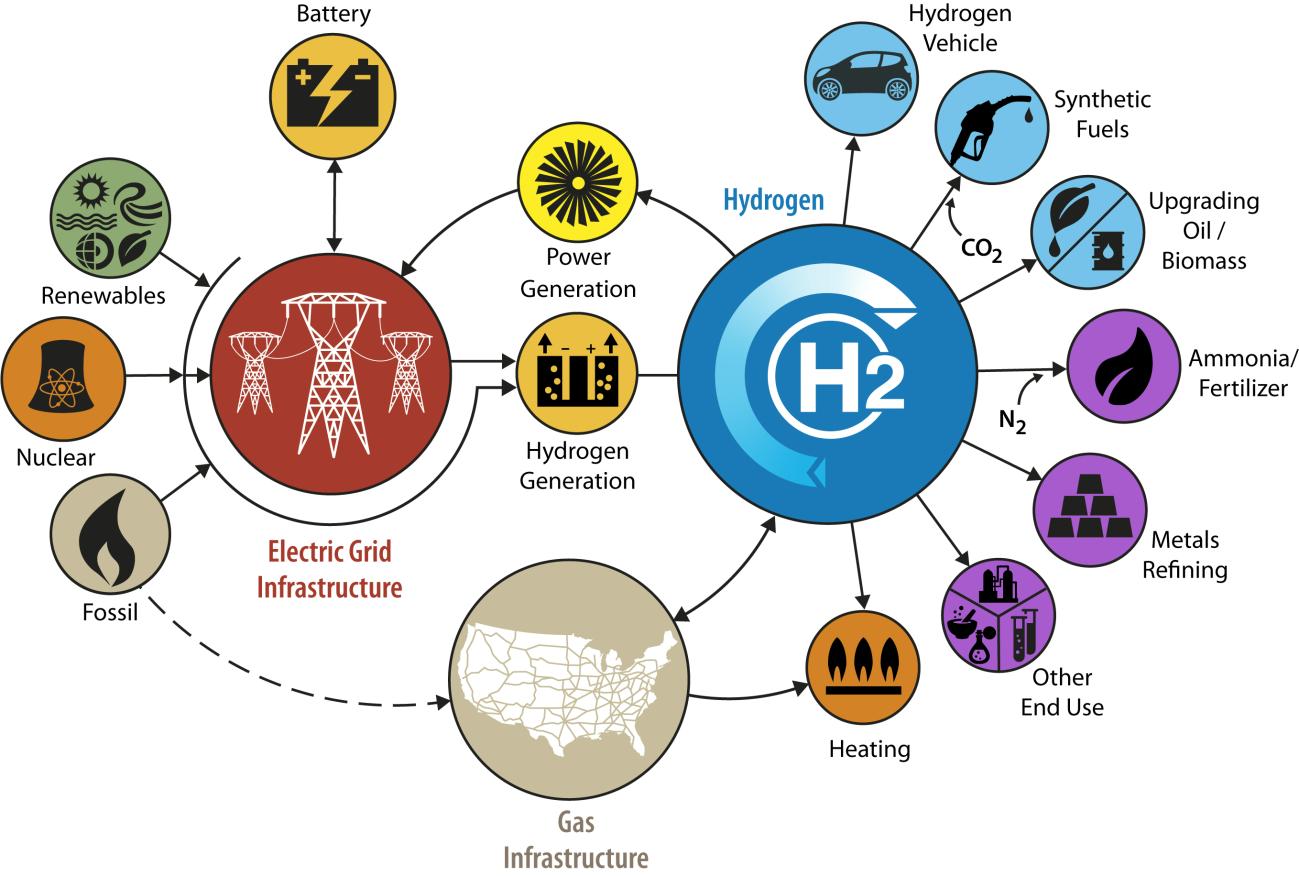

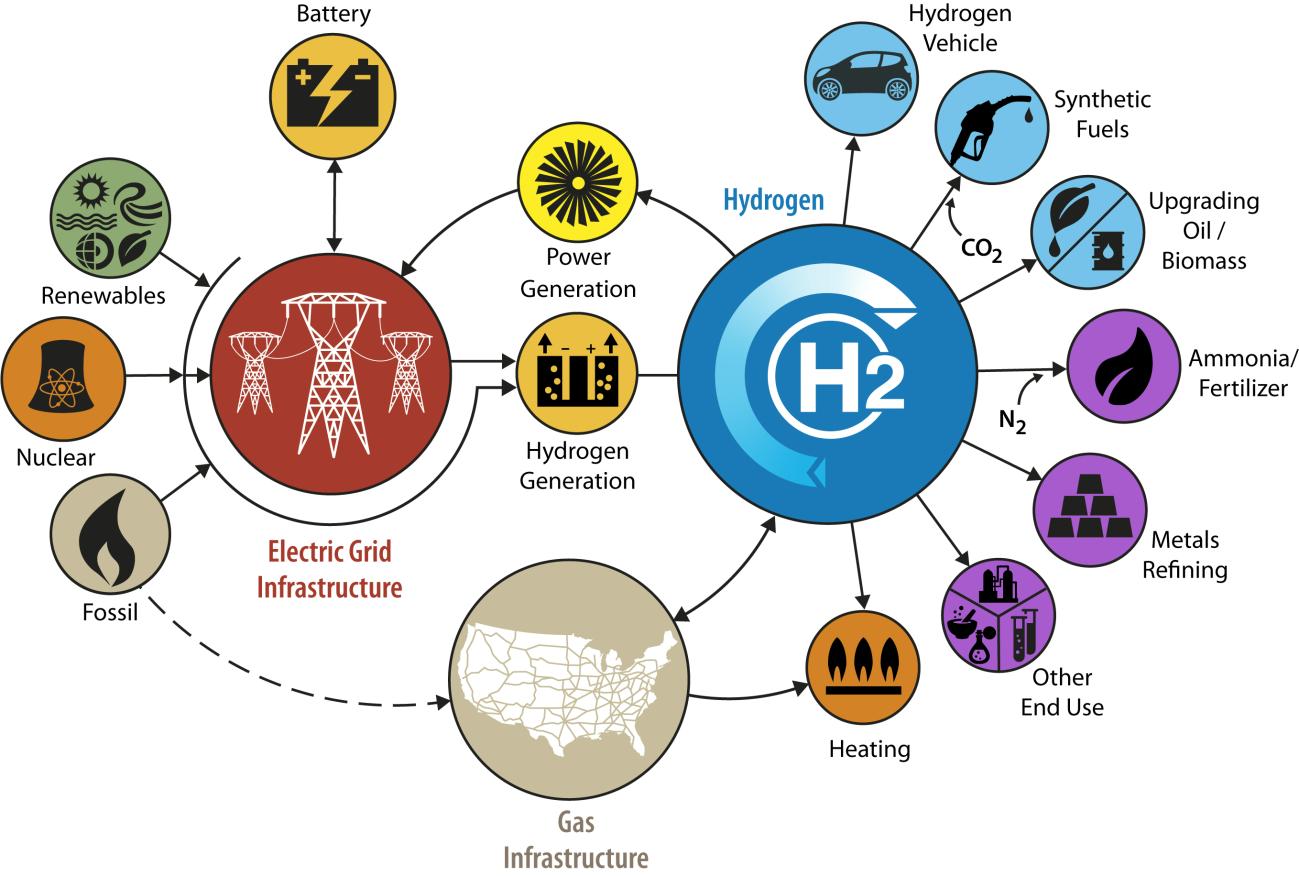

Hydrogen is valuable because it is an energy carrier that can be used in many different ways:

- As a replacement for fossil fuels in many areas

- As a feedstock for industry and chemicals

- As a way of supporting renewable power and heat

Home heating and Lighting explores the possibility of using hydrogen in our homes, and how that would require adapting our ovens, stoves and boilers. Travel and Transport covers hydrogen cars as well as a range of other vehicles, including forklifts, buses, trains and trucks. Business and Industry explores how most of the hydrogen produced today is used in industry as a feedstock to make products like fertilisers and metals.

Supporting renewable energy

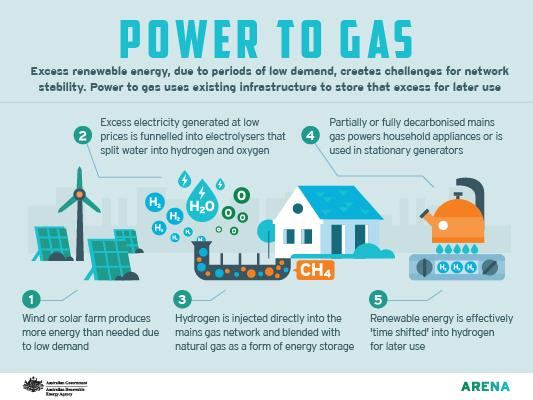

Each year, the amount of renewable energy (such as wind power, biomass and solar power) used globally grows. While weather-based energy sources are clean and sustainable, we have no control over when they provide power – they only work when the wind blows or the sun shines. Sometimes the amount of renewable energy available does not match demand, so other energy sources such as natural gas are required to make up the difference. Along with batteries or hydroelectric dams, hydrogen could change this by storing up surplus energy for when it is needed. The gas can be stored in pressurised containers, or underground given suitable geology such as salt caverns.

One example of storing energy as hydrogen is a process called power-to-gas.

Just like with any energy conversion, there will be some losses involved in the power-to-gas process. Nevertheless, hydrogen has the potential to be a cheaper energy store than batteries. Examples of power-to-gas include GRHYD, a project in the Dunkirk region run by energy company ENGIE and supported by the French Government; and German project Energiepark Mainz.

Using hydrogen safely

Hydrogen is flammable and ignites easily, which carries safety risks. Hydrogen gas has unique physical and chemical properties; understanding the way it behaves in different situations is vital so it can be used safely. Organisations such as the UK Health and Safety Executive and Hydrogen Europe, as well as private companies, are conducting research into the operational risks of using hydrogen for new applications like heat and transport. When using a new energy source, it is important to learn as much as possible about any potential risks and how to manage them – our use of natural gas has progressed in the same way.

Hydrogen is a non-toxic gas with no colour, taste or smell. It burns with a very pale blue flame and does not produce hot ash or smoke, so it is difficult to detect when it is burning or leaking. One option is to add a suitable strong-smelling chemical called an odorant to the gas mix so that it is easy to detect – an odorant is what gives natural gas its distinctive smell. However, odorants can contaminate technologies, such as fuel cells , which require pure hydrogen gas.

Hydrogen gas has a lower density than air, which means that if it leaks, it will quickly float away. However, as with other flammable gases, if the leak is indoors the gas could build up and cause a fire or explosion. Buildings using hydrogen should include suitable ventilation for pipes and boiler systems – rooms can also include one-way, mechanical ventilation which will allow any gas that builds up to escape. Infra-red sensors can be installed to detect leaks at the meter.

- Methods of making hydrogen The main processes for making hydrogen use natural gas, coal, or electricity with water.

Other options for hydrogen production Biomass, solar power and nuclear power could all be used to make hydrogen in the future.

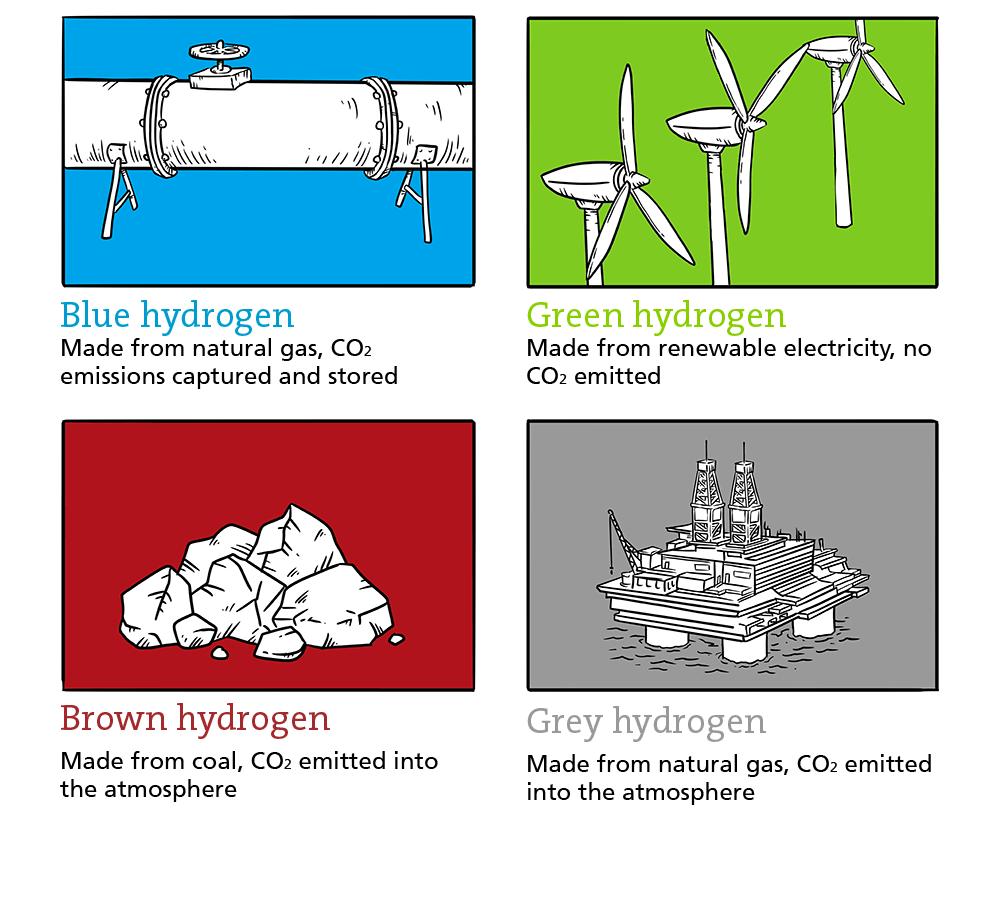

The different ‘colours’ of hydrogen The environmental impact of making hydrogen depends on how it is made, and what it is made from.

Although it is a very common element, there are no large reserves of hydrogen gas on Earth. This is because it bonds with other elements, so the hydrogen we need is locked up in other substances. By using energy (heat, electricity etc) it is possible to separate out the hydrogen from feedstockssuch as water and methane.

Today, over 95% of dedicated hydrogen production is from natural gas or coal, which produces greenhouse gas emissions. If we want to use hydrogen to help reduce greenhouse gas emissions, switching to a low-carbon method of production is required. The environmental impact of making hydrogen depends on what it is made out of (the feedstock) and the source of energy used to drive the process.

Current methods of making hydrogen

Hydrogen from fossil fuels

The most common method of making hydrogen today is called steam methane reformation (SMR), which combines methane (from natural gas) and water at very high temperatures (approximately 900°C) to produce a mix of carbon monoxide, carbon dioxide (CO2) and hydrogen. By controlling the amount of air, water and methane in the reaction, engineers can alter the SMR process and change the amount of energy required and waste gases produced.

Hydrogen can also be made from coal in a process called gasification. A syngas is created using coal and water at high temperatures. Above 750°C, the carbon in coal reacts with water to form a mix of gases, including hydrogen and carbon dioxide. The coal is used to provide the heat that the reaction needs to work.

Using fossil fuels to make hydrogen produces waste greenhouse gases. To make the process environmentally friendly, waste gases must be prevented from reaching the atmosphere by using carbon capture usage and storage (CCUS) technology, which can remove and store up to 97% of the CO2 emissions that are produced. However, CCUS is not widely commercially available at present.

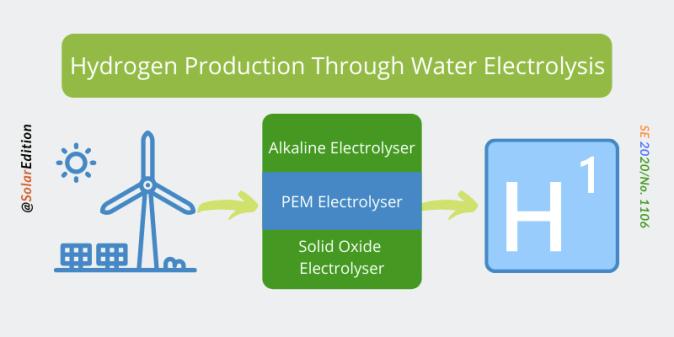

Hydrogen from electricity

Electrolysis is a process which uses electricity to split water into hydrogen and oxygen, using an electrolyser .

The electricity can come from a range of sources, such as wind power, solar power, nuclear power or fossil fuels. Any hydrogen produced is low carbon as long as the electricity used in the process is from low-carbon energy sources. Today, less than 5% of dedicated hydrogen production uses electrolysis; the process is expensive due to the cost of electricity (especially from low-carbon sources) and equipment. Production costs are expected to decrease as the cost and size of electrolysers improve.

Unlike other methods, electrolysis works at low temperatures, typically 20-100°C, and is capable of producing hydrogen at a range of scales. For example, ITM Power has built eight hydrogen refuelling stations in the UK, each supplied by an on-site electrolyser powered by renewable energy. There are large-scale electrolysis projects too; ENGIE plans to install electrolysers on an offshore platform in the North Sea, powered by electricity from offshore wind power. The hydrogen produced can be brought onshore using existing gas pipelines.

Other options for hydrogen production

Another energy carrier from which hydrogen is made is biomass . Using gasification, biomass is heated and mixed with steam and oxygen to produce hydrogen without combustion (burning). Scientists and engineers are always on the hunt for new methods of making hydrogen, such as novel ways of using solar power or nuclear power to break apart water at a range of temperatures to get hydrogen and oxygen.

The different ‘colours’ of hydrogen

Hydrogen is often described by a colour. This does not describe what it looks like, but how environmentally friendly the process of making it is.

The CCUS technology needed to safely remove greenhouse gas emissions and store them is not yet widespread. As of the start of 2020 there are just 19 ‘large-scale’ projects in operation worldwide; it is likely that blue hydrogen will become more common as CCUS becomes cheaper and more widely used.

Nevertheless, blue hydrogen is currently estimated to be the cheapest option for producing hydrogen gas in a low-carbon way. As the availability and price of renewable electricity improves, coupled with a fall in the costs of electrolysis equipment , green hydrogen could potentially become the dominant type in use over the next 30 years.

- Gas pipelines Hydrogen could be pumped through gas pipelines, similar to natural gas today.

- Compressed gas Hydrogen gas can be compressed into containers for transport on trucks or trains.

- Liquid hydrogen Cooling hydrogen so that it is in liquid form allows it to store a lot more energy in a smaller space, but the cooling process is expensive and energy-intensive.

Like fossil fuels, hydrogen is often produced far away from where it will be used, and must be transported over long distances to homes, factories or refuelling stations. It is less dense than air, so it will escape and quickly disperse if there are any leaks in a container or pipe. Additionally, hydrogen is not very energy dense by volume when compared to traditional fuels like petrol. For example, to match the energy stored in one litre of petrol, you would need over 18 litres of hydrogen at high pressure (200 bar ). Part of the challenge of transporting hydrogen is finding ways of increasing its energy density – this could mean moving it around as a liquid or a high pressure gas, safely and cheaply.

Gas pipelines

For long-distance transport, hydrogen can be pumped through gas pipelines. There are hundreds of kilometres of hydrogen pipes in the world already, for example in the USA, Germany and Belgium. Maintaining a system of pipes requires constant work; hydrogen gas leaks from small gaps, so there must be regular checks for wear and tear, particularly at valves and joints. Some countries already have wide networks of natural gas pipes linked up to homes and businesses, which could be converted to carry hydrogen. See Home heating and cooking for more.

Compressed gas and liquid hydrogen

One way of increasing the amount of energy stored by hydrogen is to compress a lot of gas into a small container, usually made of aluminium reinforced with plastic, fibreglass or carbon fibre. The containers can then be loaded onto trucks and delivered to where they are needed – no hydrogen is lost as long as the container is secure.

At extremely low temperatures (below -253°C) hydrogen becomes a liquid. Liquid hydrogen is 800 times denser than hydrogen gas in the atmosphere, so liquefaction is an attractive option for storing a lot of energy in a small space. Liquefaction technology has been used since the 1960s to transport natural gas, but for hydrogen the process is more expensive and energy intensive, as the temperatures required are much lower (-253°C compared to -162°C).

Liquid hydrogen is transported by road, rail or ship, depending upon the distance and the amount needed. Over time heat will gradually leak into the cold store, converting the liquid to gas and causing some of the hydrogen to be lost.

Future options for moving hydrogen around

Research is ongoing to create solids or liquids that can absorb large volumes of hydrogen, for easy transportation. One option is to convert hydrogen into liquid ammonia for the duration of travel – this comes with a different set of hazards to hydrogen, as ammonia is toxic. The hope is that these future options can address many of the cost and safety concerns surrounding current methods of high-pressure or liquid storage.

- Methods of home heating Homes and businesses around the world are mainly heated by coal and natural gas. To reduce greenhouse gas emissions, these fuels could be replaced by electricity, low-carbon gas (such as hydrogen) or heat networks.

- Hydrogen in the gas network We can potentially use existing gas pipes to carry hydrogen for heating homes and businesses.

- Using hydrogen safely in the home Heating and cooking appliances would need to be adapted or replaced, and there are cost and safety considerations.

- Case studies in the UK The UK is leading the way in hydrogen heating projects.

Whether it is for warming a room, cooking a meal, or taking a shower, heating in homes requires a lot of energy. Producing heat without using fossil fuels is a big challenge – in 2017, 23% of all the energy consumed globally was used for space heating, water heating and cooking, and only 10% of this was produced from renewable sources. There are a number of low-carbon heating methods we could use instead, which include burning hydrogen.

Methods of home heating

Global heat generation is dominated by coal and natural gas, which are relatively cheap and abundant. When they burn, they produce harmful emissions such as carbon dioxide (CO2) and nitrogen oxides (NOx) which contribute to air pollution and climate change.

Three sustainable heating methods we could use instead of fossils fuels are:

1.Low-carbon electricity, used to power storage heaters and heat pumps

2. Heat networks (also called district heating) – a series of pipes deliver heat to homes from a central, low-carbon energy source

3. ‘Green’ gases – hydrogen, synthetic natural gas or biogas

Replacing fossil fuels for heating is an enormous task, and it is likely that all three of these options will be required in some form. This guide explores the potential of the ‘green’ gas option, and how hydrogen could contribute to sustainable, low-carbon home heating.

Hydrogen in the gas network

Some countries such as the Netherlands and the UK already have a national network of natural gas pipes linked up to most homes and businesses. People in these countries are used to using natural gas for heating and cooking, and hydrogen could act as a low-carbon replacement. Just like natural gas, hydrogen can be transported through pipes and burned in the home using a boiler or stove; the only waste products at the point of use are water and some NOxgases.

20% hydrogen

Mixing some hydrogen into the natural gas we use today could reduce greenhouse gas emissions without disrupting homeowners and businesses. For example, a gas mix that is a blend of 20% hydrogen and 80% natural gas by volume can be used in an existing natural gas network without changing any pipes or appliances – this enables a small CO2 saving (about 6%) compared with just using natural gas. An example of this is the HyDeploy project at Keele University in the UK. A second phase of the project will see Northern Gas Networks supplying around 650 homes and businesses in the north east of England with a hydrogen and natural gas blend.

100% hydrogen

Converting a natural gas network to use 100% low-carbon hydrogen could save significantly more CO2, but it is a bigger logistical challenge. While it would be unusual, switching over to a new type of gas is not unprecedented; during the mid-20th century in the UK, USA and Australia, many homes switched from using so-called town gas to natural gas. The UK switch-over took 10 years to complete and required the replacement or modification of over 40 million household gas appliances.

Gas networks have two main parts – the transmission system, which is like a motorway that moves gas long distances at high pressure, and the distribution system, which is like a series of smaller roads moving gas into homes and offices at lower pressure.

The distribution system can be adapted to use hydrogen instead of natural gas. Homes and offices would need to modify or replace their gas appliances, but infrastructure would essentially remain the same. Old gas pipes, valves and joints need to be checked for wear and tear, as hydrogen leaks easily from small gaps. In the UK, new plastic (polyethylene) pipes are being installed to replace older iron and steel versions, and these new pipes can safely carry hydrogen at low pressures, with little risk of leakage.

It has been argued that converting a natural gas network to carry hydrogen would save money compared to other forms of low-carbon heat, due to it minimising disruption and reducing the amount of new, expensive infrastructure needed. For instance, the H21 suite of gas industry projects aims to provide evidence in support of re-purposing the UK gas network. However, existing pipelines would still need some investment and the transmission system would need to be modified or replaced. Transmission systems use steel pipes to carry natural gas at high pressures (up to 75 bar in the UK), and steel can be damaged by high-pressure hydrogen, becoming weak and brittle.

Using hydrogen safely in the home

If natural gas is replaced with 100% hydrogen, heating and cooking appliances will need to be adapted or replaced. This is because hydrogen has different properties from natural gas – for example, it burns at a higher temperature. Companies such as Worcester Bosch, Giacomini and BDR Thermea (BAXI) are already developing hydrogen-ready appliances for use in homes. These appliances would work normally with natural gas, but could also be used with hydrogen if the gas supply switched over. An Australian company (Heatlie) has even developed a hydrogen-fuelled barbecue. Research projects such as Hy4Heat and HyHouse are testing to make sure these new appliances are safe and easy to use.

Boilers

Natural gas boilers have a part called a flame failure device, which uses sensors to stop gas from flowing if the flame goes out. The sensors used in natural gas boilers do not work with hydrogen, but engineers are working on new versions that do, using infra-red or ultra-violet light. To make sure hydrogen boilers are safe, these devices need to be fast acting and reliable.

Fireplaces

Hydrogen burns with a very pale blue flame which is almost invisible to the naked eye. Adding a chemical called a colourant to the flame would make it easier to see, which is safer and more aesthetically pleasing. Work is ongoing to find a suitable colourant that is cheap, non-toxic and compatible with hydrogen. An alternative option would be to design a heating element that glows when in use.

Cookers and ovens

Hydrogen cookers would require a re-designed burner, in order to manage the higher temperatures hydrogen burns at and to limit the release of harmful NOx gases. This may include reducing the size of the burner holes, using new materials, or other methods of limiting oxygen concentration at the point of ignition. Using hydrogen is not expected to impact on cooking performance or require new kitchen utensils.

UK hydrogen for heating pilot projects

There are a number of studies and projects in the UK testing out whether replacing natural gas with hydrogen is safe, how much it would cost, and how disruptive the process would be.

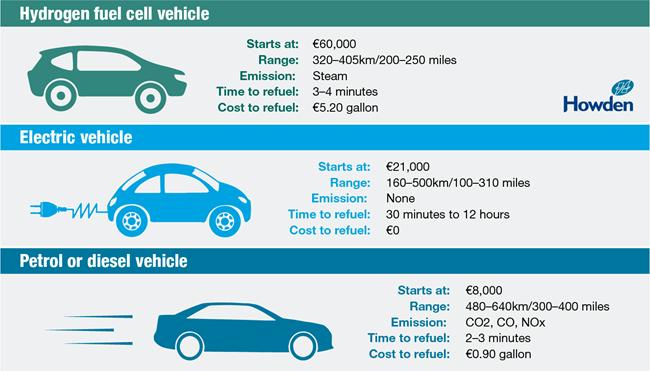

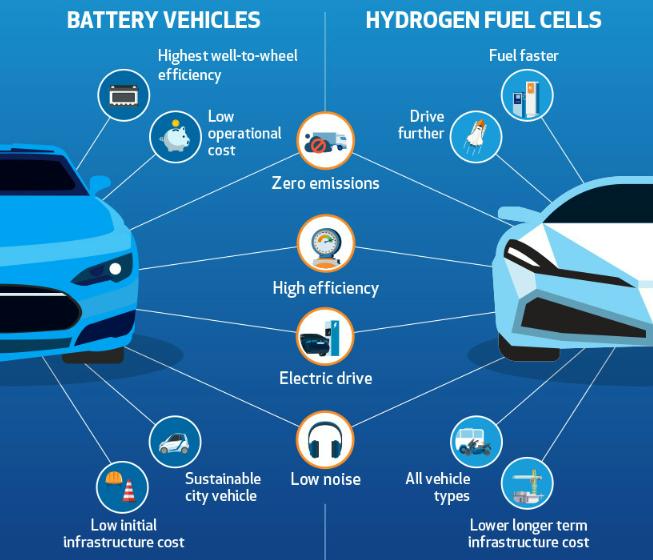

Low-carbon transport We can use electricity from batteries or hydrogen fuel cells to power vehicles in a low-carbon way.

How do hydrogen cars compare? Hydrogen cars are expensive but have longer ranges and shorter refuelling times than battery electric equivalents.

Other types of hydrogen vehicles Hydrogen could be used as a low-carbon fuel for other vehicles, including buses, trucks, ships and trains.

Around the world today, people are almost totally reliant on petroleum products for powering their vehicles (e.g. petrol and diesel). Burning these fuels for transport produces nearly a quarter of the world’s carbon dioxide (CO2) emissions, and air pollution from vehicles causes around 185,000 premature deaths each year. Despite these negative effects, the quantity of oil we use increases each year, as the number of trucks, planes and ships travelling the globe rises. Replacing fuels like petrol, diesel and kerosene will be difficult, but hydrogen is one option, alongside electricity and biofuels .

Batteries and fuel cells

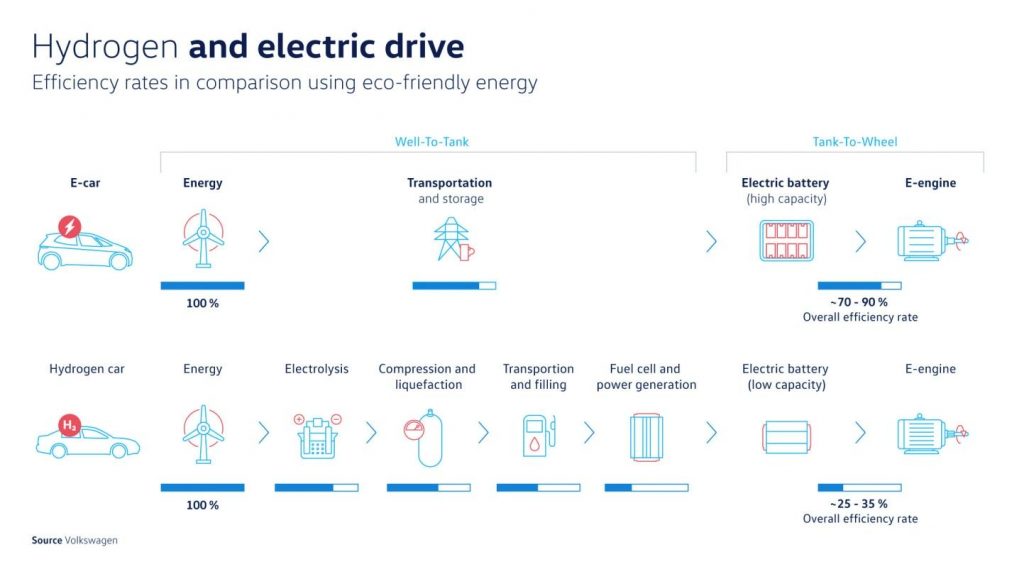

Electric cars and bikes are gaining popularity as a personal transport option – they are quiet, efficient and produce zero emissions at the exhaust pipe, which is crucial for improving air quality in cities. As long as the source of electricity is low carbon, they also help to tackle climate change.

Battery electric vehicles (BEVs) use electricity stored in a rechargeable lithium-ion battery to power the motors. In 2018, there were over 5 million BEVs in use worldwide – they are selling well in China, Europe and parts of the USA.

Batteries do not store as much energy per kilogram as other fuels, which limits the distance you can travel on one charge. They also take a long time to recharge and degrade over time. This means that electric vehicles need to be supported by a network of fast-chargers in convenient locations like motorway service stations, as well as home/office charging points. Producing batteries currently requires a lot of energy and resources, including minerals such as lithium and cobalt.

Another way of powering vehicles with electricity is to use fuel cells. A fuel cell produces electricity on-board using a chemical reaction between hydrogen and oxygen. This is clean and efficient – the only waste product is water. As well as a supply of hydrogen and oxygen, each fuel cell uses a catalyst , usually platinum. Most fuel cells need to use very pure hydrogen (no additional gases contaminating the mix), otherwise the catalyst will stop working.

How do hydrogen cars compare?

Hydrogen cars (also called fuel cell electric vehicles or FCEVs) use fuel cells instead of batteries to provide electricity to the motors. They have longer ranges and much shorter refuelling times than battery electric equivalents.

Hydrogen cars are just starting to become commercially available – in the UK, Honda, Hyundai and Toyota have all released models. As of 2019, hydrogen cars are rare (around 13,000 worldwide), and much more expensive than similar sized battery electric, petrol or diesel cars. However, they require fewer resources and less energy to make, so costs are likely to fall if mass production begins.

Safety

Hydrogen is a flammable fuel that ignites easily (like petrol), so it must be handled responsibly. Hydrogen cars are built with this in mind and have achieved the same vehicle safety standards as all other road-legal cars. The first hydrogen fuel cell car tested by Euro NCAP (Hyundai Nexo) received the maximum five star rating for safety.

Hydrogen cars are designed with unique safety features to prevent hydrogen build-up if there is a leak – this includes sensors that can seal valves and vent gas when necessary. The hydrogen fuel is stored at high pressure (up to 700 bar ) in a tank made of carbon fibre and plastic, which is extremely strong and unlikely to leak. Tests show that the hydrogen tank on the Toyota Mirai is able to withstand being burned, crushed by 150 tonnes or shot with a gun without breaking.

Refuelling

Hydrogen cars can be filled up at a hydrogen fuelling station, similar to traditional petrol or diesel. Hydrogen fuelling stations are designed to store the gas above the ground in open areas, so any leaks or fires can be managed safely. The hydrogen nozzle is designed to be an exact fit with the fuel tank opening and will automatically dispense the gas once it is locked into place and the seal is sound. Refuelling stations are designed with lots of safety controls, including infra-red sensors for hydrogen leak detection and mandated safety distances between buildings, fuel pumps and pipework.

Currently only a tiny number of fuelling stations exist (as of 2019 there are just 10 in the UK), which alongside costs has been a key factor slowing the deployment of hydrogen cars. This is a ‘chicken and egg’ problem – there needs to be plenty of fuelling stations to encourage people to buy hydrogen cars, but companies will only build fuelling stations if there are hydrogen cars on the road to use them. Government policy could help solve the problem, by incentivising a national network of refuelling stations.

Using hydrogen in other types of vehicles

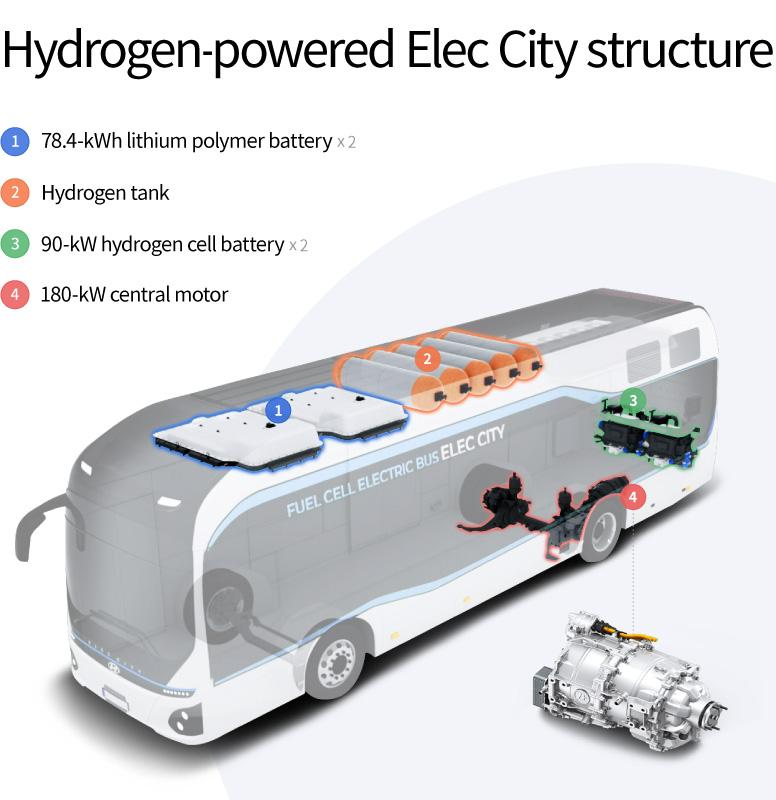

Both battery electric and hydrogen cars are set to become more popular in the years ahead as some countries begin to phase out new diesel and petrol passenger cars. However, batteries are currently not well-suited for heavier vehicles, which require the longer ranges and short refuelling times that hydrogen can provide. Hydrogen-powered forklifts and buses are already operating in several European cities, small numbers of trucks and trains are starting to be deployed, and technologies are being developed for planes and ships.

Trucks

Hydrogen is well suited for the long-haul trucking sector; trucks fuelled by hydrogen have a similar range (500-750 miles) and refuelling time (15 mins) to diesel trucks, but they do not produce harmful and polluting emissions. Batteries are heavy and bulky, cost more, and take longer to charge than refuelling either current diesel or hydrogen trucks. Freight companies are starting to embrace hydrogen – 10,000 new hydrogen trucks were put onto the road in China in 2019 alone.

Buses

Hydrogen buses are starting to appear in cities, often aimed at reducing air pollution in busy, congested areas. The buses have longer driving ranges than battery electric equivalents and can be refuelled quickly in a depot. Around 500 hydrogen buses are in operation worldwide, mainly in Europe and North America. The JIVE2 project aims to deploy new buses (and the fuelling stations they need) across 14 European cities, including Brighton, Toulouse and Dundee. In the UK, hydrogen fuel cell buses are in use in Aberdeen and are being trialled in London.

Forklifts

Of all hydrogen vehicles, forklifts are the most common – there are already over 25,000 in use worldwide. Forklifts are often used in enclosed spaces like warehouses; hydrogen fuel cells are perfectly suited for this, as they are quiet and do not produce harmful exhaust fumes. Additionally, fuel cells take up less space than batteries, and they only take a few minutes to refuel.

Trains

Trains are usually powered by diesel, or electricity through overhead lines or a third rail. Where these lines are unavailable, electricity can also be made on-board by hydrogen fuel cells. The world’s first hydrogen trains (made by Alstom) started running in 2018 in Germany, with more on the way. There are also plans to introduce hydrogen trains in Japan and the UK.

Planes

Hydrogen has been used as a lifting gas in airships, but it is unlikely to ever be used as fuel for large passenger aeroplanes because of its low energy density compared to kerosene – it would be almost impossible for a plane to safely carry the vast amount of hydrogen fuel needed for a long-haul flight. The start-up company ZeroAvia is developing a six-seater hydrogen-fuelled plane with a potential range of 500 miles, but commercial hydrogen planes are unlikely to be commonplace.

Boats and shipping

Cargo ships are usually powered by heavy fuel oil, which is cheap but highly polluting – the shipping industry produces 3% of global greenhouse gas emissions and is viewed as one of the most difficult sectors to clean up. Hydrogen could be used to make ammonia as an alternative fuel, which is more energy dense – however it is toxic. On a smaller scale, there are a number of pilot projects for hydrogen ferries, for example HyDIME.

- Current uses for hydrogen Most of the hydrogen made today is used in the petroleum refining process or as one of the main chemical ingredients in fertilisers.

- Safety and regulations Technical and health regulations for hydrogen have been developed through 90 years of industry experience.

- New jobs and skills Using more hydrogen could mean more jobs in construction, manufacturing, industry and engineering

Although the idea of using hydrogen might be new to some, hydrogen gas has been used for decades in industry to make a wide range of products. 70 million tonnes of hydrogen are produced worldwide each year (as well as 48 million tonnes created as a by-product from other industrial processes), enough to heat every home in Europe. As of 2019, nearly all of this hydrogen is produced from fossil fuels . The global market for hydrogen production is growing and worth over $115bn (£90bn) – growth could speed up if hydrogen is needed for new applications like heat and transport.

Current uses for hydrogen

Today, the most common uses for hydrogen are:

1.Petroleum refining – reducing the amount of harmful sulphur oxides contained in fuels, as well as for splitting crude oil into useful hydrocarbons such as ethane and liquid petroleum gas.

2.Ammonia production – this is one of the three key ingredients in fertilisers. This allows us to grow food in fields that would normally lack key nutrients.

3. Methanol production – a useful chemical used in paints, fabrics and fibres.

4. Steel production – hydrogen is used in the steel making process, and engineers are testing ways of using it to replace coal entirely.

5. Other minor uses include parts of the manufacturing process for plastics, resins, flat sheets of glass and silicon microchips, as well as a coolant for large electrical generators.

Space travel

Hydrogen was first used for space exploration by NASA in the 1960s and it has remained an important part of space travel ever since. NASA and the European Space Agency both use hydrogen as a propellant in rocket fuel, as it is very light and burns at a high temperature. Hydrogen fuel cells are also used as a power source for spacecraft and space vehicles. On the Space Shuttle, three fuel cells were used to power all the electronics in the craft. As a bonus, fuel cells produce water as a waste product, which can be consumed by astronauts.

Safety and regulations

Industrial companies have been using hydrogen since the 1930s, when the gas was first used as a generator coolant by the Dayton Power & Light Co. in Ohio, USA. Over the following years, companies and governments have worked together to create regulations and codes that ensure using hydrogen is safe and low risk. There are at least 16 international bodies developing guidance and over 400 different standards worldwide supporting hydrogen development and deployment. This covers everything from how to store hydrogen securely, to regulations on the types of pipes and valves used. Although these regulations were designed for business and industry, this know-how can also be applied when using hydrogen in new areas, such as safely heating a home.

Other industrial uses for hydrogen

If current trends continue, the amount of hydrogen needed in industry is set to grow as the world uses more steel, methanol, ammonia and petroleum products each year. There are possible new roles for hydrogen too – because it burns at a very high temperature, hydrogen gas could replace fossil fuels entirely in some high-temperature (over 400°C) industrial applications, such as steel making and fuelling cement kilns.

About one third of all the hydrogen produced today is a by-product from industrial processes, such as the production of chlorine, propane and high-octane fuels. This hydrogen can be used for making methanol and steel. However, as it contains small amounts of other gases (carbon dioxide, oxygen, methane or argon), it is not pure enough for use in fuel cells or petroleum refining without further treatment.

New jobs and skills

Supporters of hydrogen argue that if it is used more widely, it would create a significant number of skilled jobs. Producing and transporting hydrogen could boost the construction, manufacturing and machinery industries; skilled technical workers will be needed at companies making hydrogen technology, vehicles and appliances. Countries which are early adopters of hydrogen could have the opportunity to capitalise on intellectual property, knowledge and skills.

In the UK, a number of new hydrogen projects are based in existing industrial areas. This is practical, as there are intensive energy users (e.g. steel production), and a local population that have the skills to be re-trained to work with hydrogen. Often, industrial centres are in a geographically beneficial position due to their location near salt mines (for storage) and the coast (for carbon capture usage and storage capabilities).

Examples include the HyNet Project, which aims to develop hydrogen for heating, power and transport in the north west of England, expected to create 5000 new jobs by 2025; and the Zero Carbon Humber project, centred around making hydrogen at an industrial hub in the north east of England, an area that has suffered economically as steel, coal and manufacturing employment has been lost.

- Interest in hydrogen today While mainly used in industry today, interest in hydrogen is growing, with research and pilot projects springing up worldwide.

- How would hydrogen be most effective? Hydrogen will be better suited for some applications than others, depending on practicalities and cost.

Hydrogen stands out as an appealing and flexible energy carrier . If produced cheaply and cleanly, it has the potential to replace fossil fuels for applications that cannot easily be electrified. However, the abundance, low cost and convenience of fossil fuels means that hydrogen has not been used widely outside of industrial processes. Due to a number of factors, including the need to reduce greenhouse gas emissions, this could be about to change.

Interest in hydrogen today

Today, hydrogen is most commonly used in industry, mainly for petroleum refining and production of ammonia and methanol. In addition, several countries are beginning to increase development of hydrogen technology and infrastructure. Different countries are using hydrogen for different reasons – it could be to meet climate change and emissions targets (Europe), the need to reduce reliance on coal (China) or a desire to improve low-carbon transport and develop a hydrogen export industry (Australia).

How would hydrogen be most effective?

We have used hydrogen in lots of ways since its discovery in the 1700s – to fill blimps and airships, make fertilisers and turn crude oil into petroleum products. However, hydrogen has the potential for much more varied applications, although it is not yet clear which will take precedence. As with any energy source, the usefulness and value of hydrogen will depend on a number of factors which vary with location, sector and end use. How hydrogen continues to impact on our lives will depend on these new applications. Some of the most important factors which will determine the future role of hydrogen include:

Cost

Predicting the future cost of hydrogen is difficult, as it depends on the method of production and the price of the feedstock needed to make it. ‘Green’ hydrogen, which is made using renewable electricity and water, is currently the most expensive. ‘Blue’ hydrogen, made using natural gas, has been touted as a cheaper option that is still low carbon (carbon capture usage and storage (CCUS) technology is used to prevent greenhouse gases being emitted). However, there are still questions over the availability of CCUS, and how it will work at scale.

What is clear is that renewable energy, hydrogen equipment and CCUS are all becoming cheaper. Optimistic predictions expect ‘green’ hydrogen to roughly halve in cost by 2030, which would make using it a lot more attractive as an alternative to fossil fuels.

Climate change and public awareness

Climate change has risen up the agenda due to the impact of extreme weather events, such as wildfires, floods and heatwaves. High-profile climate protests were often in the news in 2019, led by groups such as Extinction Rebellion and the Sunrise Movement. At the same time, governments and businesses are starting to recognise the risks of climate change and the need to end reliance on fossil fuels.

Some countries, such as the UK, France and Norway, have committed to the ambitious target of eliminating all greenhouse gas emissions by the middle of the 21st century. To meet this target, hydrogen has been cited as an essential tool. This is likely to drive demand for hydrogen in advanced economies sooner than it would in developing economies, where access to energy or switching away from coal are a higher priority than decarbonising supplies.

Infrastructure and technology development

Support from both public and private investors can kick-start the process of building hydrogen infrastructure. Alongside governments, support for new hydrogen projects could come from a range of sources, such as gas companies, car manufacturers and engineering firms. For instance, the Hydrogen Council, founded in 2017, is an initiative led by a number of companies working in energy, transport and industry, and works to boost investment in hydrogen and fuel cells. However, private investment is unlikely to occur without some significant public policy or tax interventions. The state of infrastructure and technology will again vary from place to place; countries like the UK, which have an established gas grid, may be more likely to seek alternative gases such as hydrogen to heat homes. At a more local scale, areas which have heavy industries may be better suited to hydrogen production because of existing infrastructure or the skills of the local workforce. When it comes to personal transport, there is a lot more interest and investment in using batteries for cars rather than fuel cells. However, hydrogen may be more suited for powering buses, forklifts and freight trucks.

Copyright © Euro India. All Rights Reserved.