- Low-carbon transport We can use electricity from batteries or hydrogen fuel cells to power vehicles in a low-carbon way

- How do hydrogen cars compare? Hydrogen cars are expensive but have longer ranges and shorter refuelling times than battery electric equivalents

- Other types of hydrogen vehicles Hydrogen could be used as a low-carbon fuel for other vehicles, including buses, trucks, ships and trains

Around the world today, people are almost totally reliant on petroleum products for powering their vehicles (e.g. petrol and diesel). Burning these fuels for transport produces nearly a quarter of the world’s carbon dioxide (CO2) emissions, and air pollution from vehicles causes around 185,000 premature deaths each year. Despite these negative effects, the quantity of oil we use increases each year, as the number of trucks, planes and ships travelling the globe rises. Replacing fuels like petrol, diesel and kerosene will be difficult, but hydrogen is one option, alongside electricity and biofuels .

Batteries and fuel cells

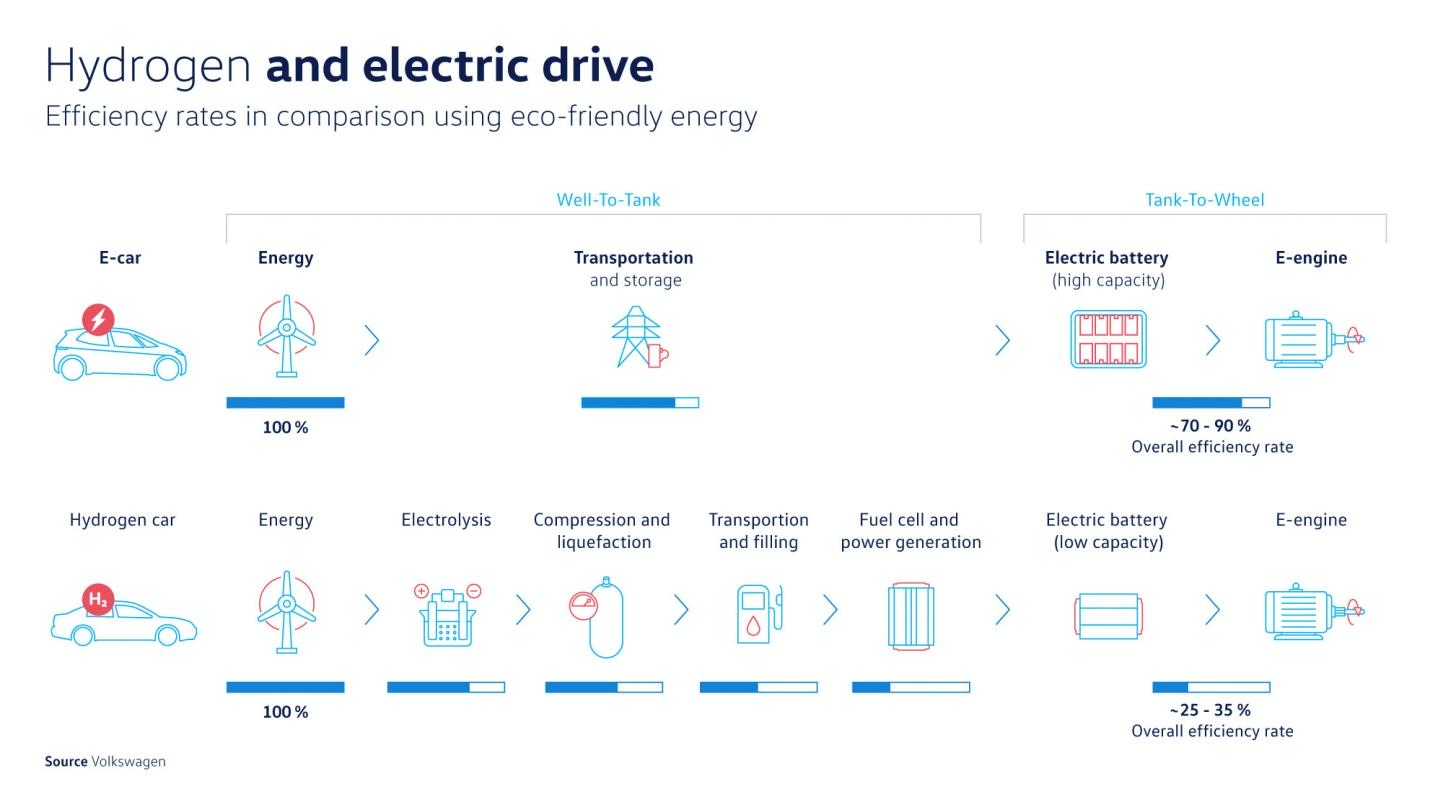

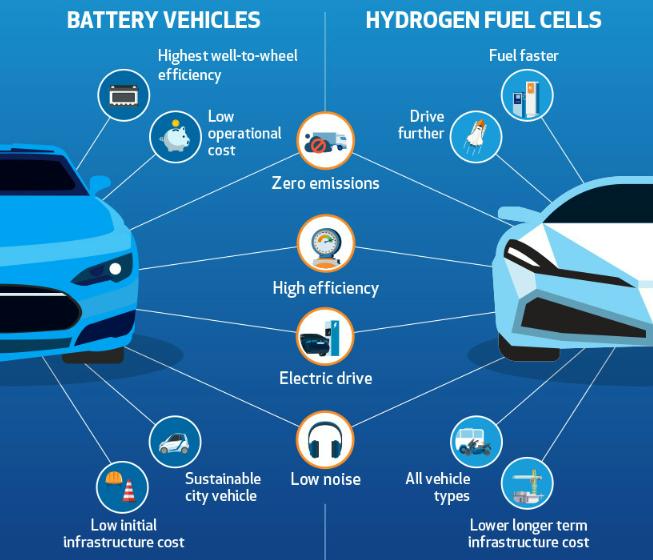

Electric cars and bikes are gaining popularity as a personal transport option – they are quiet, efficient and produce zero emissions at the exhaust pipe, which is crucial for improving air quality in cities. As long as the source of electricity is low carbon, they also help to tackle climate change.

Battery electric vehicles (BEVs) use electricity stored in a rechargeable lithium-ion battery to power the motors. In 2018, there were over 5 million BEVs in use worldwide – they are selling well in China, Europe and parts of the USA.

Batteries do not store as much energy per kilogram as other fuels, which limits the distance you can travel on one charge. They also take a long time to recharge and degrade over time. This means that electric vehicles need to be supported by a network of fast-chargers in convenient locations like motorway service stations, as well as home/office charging points. Producing batteries currently requires a lot of energy and resources, including minerals such as lithium and cobalt.

Another way of powering vehicles with electricity is to use fuel cells. A fuel cell produces electricity on-board using a chemical reaction between hydrogen and oxygen. This is clean and efficient – the only waste product is water. As well as a supply of hydrogen and oxygen, each fuel cell uses a catalyst , usually platinum. Most fuel cells need to use very pure hydrogen (no additional gases contaminating the mix), otherwise the catalyst will stop working.

How do hydrogen cars compare?

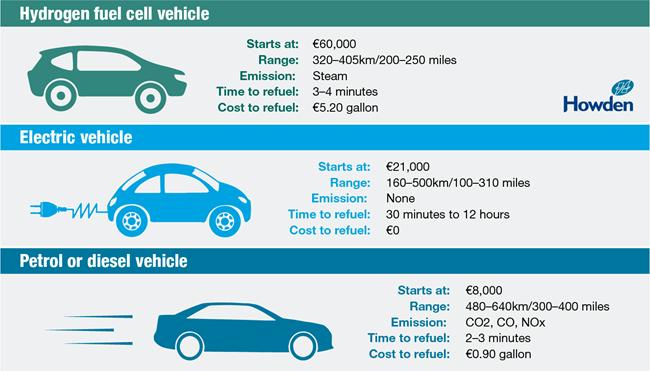

Hydrogen cars (also called fuel cell electric vehicles or FCEVs) use fuel cells instead of batteries to provide electricity to the motors. They have longer ranges and much shorter refuelling times than battery electric equivalents.

Hydrogen cars are just starting to become commercially available – in the UK, Honda, Hyundai and Toyota have all released models. As of 2019, hydrogen cars are rare (around 13,000 worldwide), and much more expensive than similar sized battery electric, petrol or diesel cars. However, they require fewer resources and less energy to make, so costs are likely to fall if mass production begins.

Hydrogen cars are just starting to become commercially available – in the UK, Honda, Hyundai and Toyota have all released models. As of 2019, hydrogen cars are rare (around 13,000 worldwide), and much more expensive than similar sized battery electric, petrol or diesel cars. However, they require fewer resources and less energy to make, so costs are likely to fall if mass production begins.

Safety

Hydrogen is a flammable fuel that ignites easily (like petrol), so it must be handled responsibly. Hydrogen cars are built with this in mind and have achieved the same vehicle safety standards as all other road-legal cars. The first hydrogen fuel cell car tested by Euro NCAP (Hyundai Nexo) received the maximum five star rating for safety.

Hydrogen cars are designed with unique safety features to prevent hydrogen build-up if there is a leak – this includes sensors that can seal valves and vent gas when necessary. The hydrogen fuel is stored at high pressure (up to 700 bar ) in a tank made of carbon fibre and plastic, which is extremely strong and unlikely to leak. Tests show that the hydrogen tank on the Toyota Mirai is able to withstand being burned, crushed by 150 tonnes or shot with a gun without breaking.

Refuelling

Hydrogen cars can be filled up at a hydrogen fuelling station, similar to traditional petrol or diesel. Hydrogen fuelling stations are designed to store the gas above the ground in open areas, so any leaks or fires can be managed safely. The hydrogen nozzle is designed to be an exact fit with the fuel tank opening and will automatically dispense the gas once it is locked into place and the seal is sound. Refuelling stations are designed with lots of safety controls, including infra-red sensors for hydrogen leak detection and mandated safety distances between buildings, fuel pumps and pipework.

Currently only a tiny number of fuelling stations exist (as of 2019 there are just 10 in the UK), which alongside costs has been a key factor slowing the deployment of hydrogen cars. This is a ‘chicken and egg’ problem – there needs to be plenty of fuelling stations to encourage people to buy hydrogen cars, but companies will only build fuelling stations if there are hydrogen cars on the road to use them. Government policy could help solve the problem, by incentivising a national network of refuelling stations.

Using hydrogen in other types of vehicles

Both battery electric and hydrogen cars are set to become more popular in the years ahead as some countries begin to phase out new diesel and petrol passenger cars. However, batteries are currently not well-suited for heavier vehicles, which require the longer ranges and short refuelling times that hydrogen can provide. Hydrogen-powered forklifts and buses are already operating in several European cities, small numbers of trucks and trains are starting to be deployed, and technologies are being developed for planes and ships.

Trucks

Hydrogen is well suited for the long-haul trucking sector; trucks fuelled by hydrogen have a similar range (500-750 miles) and refuelling time (15 mins) to diesel trucks, but they do not produce harmful and polluting emissions. Batteries are heavy and bulky, cost more, and take longer to charge than refuelling either current diesel or hydrogen trucks. Freight companies are starting to embrace hydrogen – 10,000 new hydrogen trucks were put onto the road in China in 2019 alone.

Buses

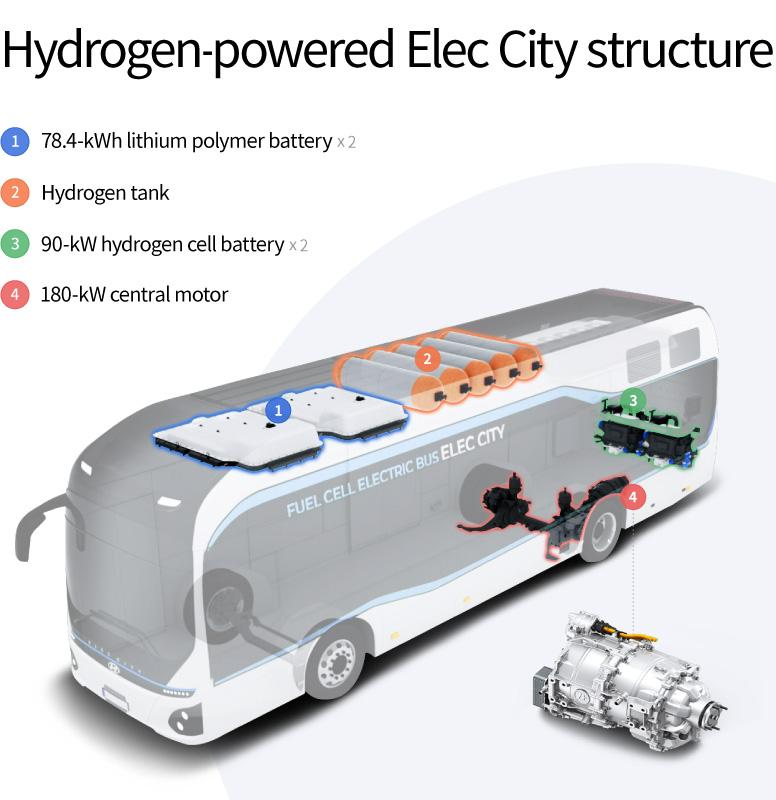

Hydrogen buses are starting to appear in cities, often aimed at reducing air pollution in busy, congested areas. The buses have longer driving ranges than battery electric equivalents and can be refuelled quickly in a depot. Around 500 hydrogen buses are in operation worldwide, mainly in Europe and North America. The JIVE2 project aims to deploy new buses (and the fuelling stations they need) across 14 European cities, including Brighton, Toulouse and Dundee. In the UK, hydrogen fuel cell buses are in use in Aberdeen and are being trialled in London.

Forklifts

Of all hydrogen vehicles, forklifts are the most common – there are already over 25,000 in use worldwide. Forklifts are often used in enclosed spaces like warehouses; hydrogen fuel cells are perfectly suited for this, as they are quiet and do not produce harmful exhaust fumes. Additionally, fuel cells take up less space than batteries, and they only take a few minutes to refuel.

Trains

Trains are usually powered by diesel, or electricity through overhead lines or a third rail. Where these lines are unavailable, electricity can also be made on-board by hydrogen fuel cells. The world’s first hydrogen trains (made by Alstom) started running in 2018 in Germany, with more on the way. There are also plans to introduce hydrogen trains in Japan and the UK.

Planes

Hydrogen has been used as a lifting gas in airships, but it is unlikely to ever be used as fuel for large passenger aeroplanes because of its low energy density compared to kerosene – it would be almost impossible for a plane to safely carry the vast amount of hydrogen fuel needed for a long-haul flight. The start-up company ZeroAvia is developing a six-seater hydrogen-fuelled plane with a potential range of 500 miles, but commercial hydrogen planes are unlikely to be commonplace.

Boats and shipping

Cargo ships are usually powered by heavy fuel oil, which is cheap but highly polluting – the shipping industry produces 3% of global greenhouse gas emissions and is viewed as one of the most difficult sectors to clean up. Hydrogen could be used to make ammonia as an alternative fuel, which is more energy dense – however it is toxic. On a smaller scale, there are a number of pilot projects for hydrogen ferries, for example HyDIME.

Copyright © Euro India. All Rights Reserved.